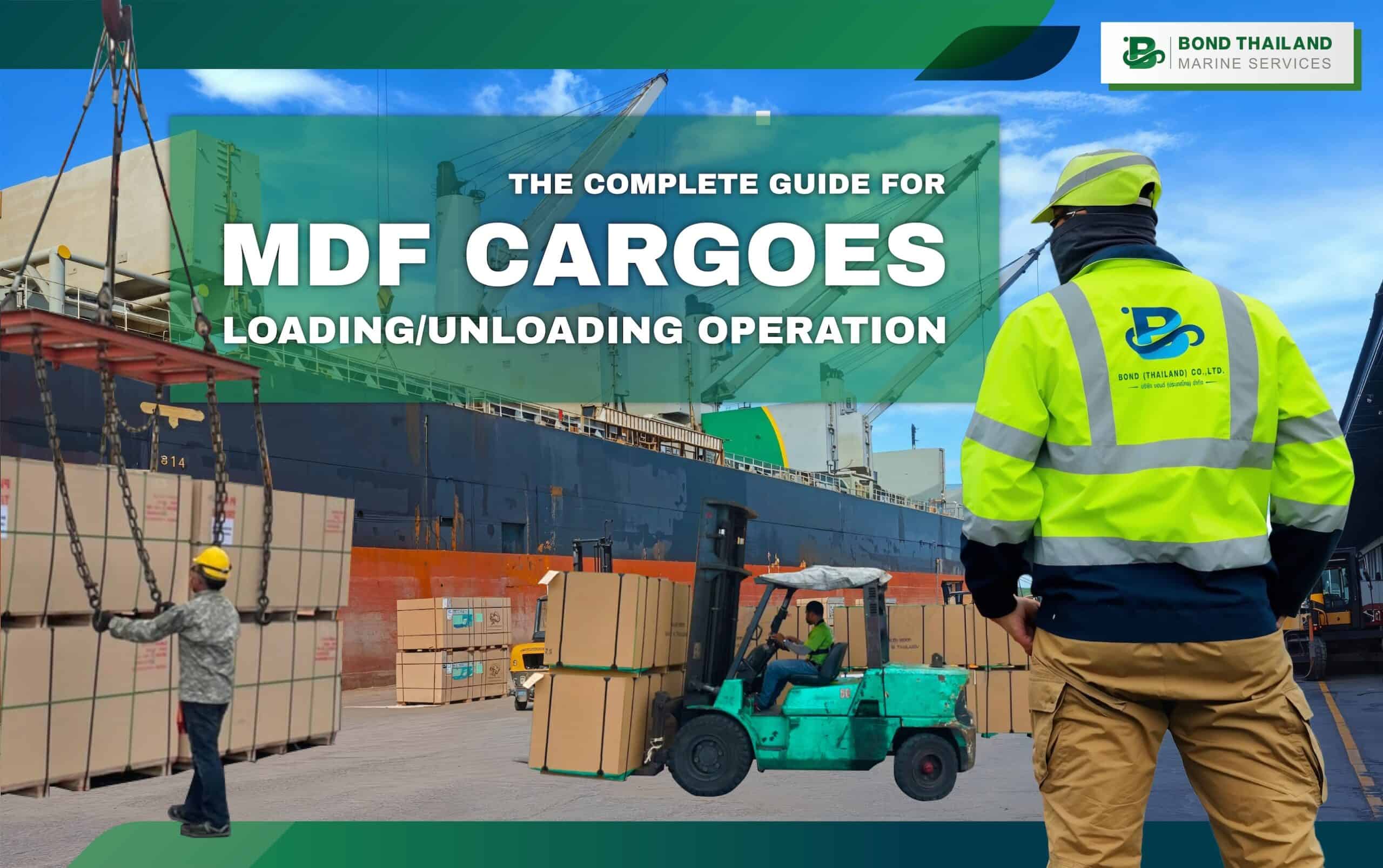

Introduction

Thailand, with its bustling ports and strategic location in Southeast Asia, has long been a hub for maritime operations. This region is a gateway for the flow of goods, and among the multitude of cargoes handled, one stands out for its ubiquity and utility: Medium Density Fiberboard (MDF). MDF is an engineered wood product known for its strength, versatility, and consistency, making it a preferred choice for a variety of applications, from furniture manufacturing to construction.

MDF is crafted by breaking down hardwood or softwood residuals into wood fibers, which are then combined with wax and a resin binder. Through the application of high temperature and pressure, these components are fused into panels. It’s a material that embodies the spirit of modern shipping: efficient, reliable, and essential for a myriad of industries.

As the world increasingly turns to MDF for its many uses, understanding the nuances of its handling becomes paramount, especially in the context of maritime shipping. Loading and unloading operations for MDF are not just about moving goods from point A to B; they’re about preserving the integrity of a product that forms the backbone of various sectors. Hence, a comprehensive guide is crucial for those involved in the maritime transport of MDF, ensuring that this valuable commodity arrives at its destination in the best possible condition.

MDF – A Maritime Commodity Unveiled

The journey of MDF from its origins to its role as a maritime commodity is a testament to human ingenuity in material science and logistics. It begins in the forest, where softwood and hardwood trees are harvested. These trees are then processed into small wood fibers, which serve as the raw material for MDF. Through a process that combines these fibers with resins and waxes under heat and pressure, durable panels are produced. This transformation from a natural resource to a highly demanded industrial product is fascinating, as it encapsulates the lifecycle of MDF, reflecting the sustainable use of forest resources when managed responsibly.

Since every commodity has its specific handling requirements, MDF is no different. This wood product comes in various standard sizes, typically ranging from 2440 x 1220 mm to 3050 x 1525 mm, and varying in thickness from 2 mm up to 30 mm or more. The density of MDF is also a crucial specification, generally lying between 500 kg/m³ to 880 kg/m³, which determines its weight and strength. These properties are significant for shipping because they influence how MDF is stowed, secured, and handled throughout its transportation.

Standardization in the dimensions and density of MDF ensures that it can be efficiently packed and containerized, optimizing space within the cargo holds and containers. The uniformity also facilitates the creation of secure stowage plans, which are vital for the safe transportation of MDF by sea. These plans take into account the weight distribution and securing points, critical for preventing cargo shifts at sea which could jeopardize the vessel’s stability.

By adhering to these specifications and standards, shipping companies can assure their clients that the MDF will be handled appropriately, maintaining its quality and structural integrity from the producer to the end-user. As such, understanding the specifications of MDF is not merely a technical requirement but a commitment to quality and safety in the global trade of this versatile material.

Pre-Loading Protocol

The pre-loading protocol is a critical stage in the maritime transportation of Medium Density Fiberboard (MDF), where meticulous planning and preparation ensure the safe and efficient handling of the cargo. Bond Thailand Marine Services, as the supervising entity, orchestrates this process with precision, aligning the operation with the highest industry standards.

Before the vessel arrives, the pre-loading process begins with a detailed assessment of cargo holds, with a particular focus on watertight integrity and cleanliness to ensure they are ready to receive the cargo. This also includes specific preparations tailored to the MDF cargo, such as:

- Verifying the dryness of cargo holds to prevent moisture-related damages to the MDF.

- Inspecting for structural integrity and absence of any residues that could contaminate the MDF panels.

- Conducting a bunker survey to check for potential fuel contamination risks.

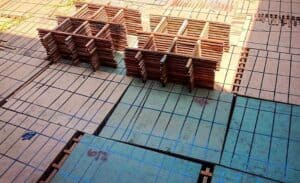

Upon the vessel’s arrival, and after the initial assessments and documentations are completed by the agent, the actual preparation for loading commences. This includes assembling a suite of specialized equipment and tools, ensuring they are readily available for the loading process. Some of these tools and equipment include:

- Forklifts for moving and stacking the MDF cargo within the holds.

- Protective materials such as dunnage and airbags to fill voids and secure the cargo against movement during transit.

- Pre-sling ropes and steel sheeting for layering between stacks of cargo, facilitating damage-free handling and distribution of weight.

The safety of the MDF cargo is of paramount importance. To safeguard against in-transit damages, Bond Thailand Marine Services implements a series of protective measures:

- Large tarpaulins are prepared to cover the cargo, protecting it from seawater and rain.

- Wire lashings are cut to the precise lengths needed to lash the cargo securely to the ship’s structure, ensuring it remains immobile throughout the journey.

- The turnbuckle, a device for adjusting the tension or length of ropes and cables, is an integral part of the cargo securing process, used to keep the wire lashings taut.

By following this comprehensive pre-loading protocol, MDF cargo is primed for a journey free from damage, securing Bond Thailand Marine Services’ reputation for excellence in maritime cargo handling

Loading Strategies for MDF

The loading of Medium Density Fiberboard (MDF) onto a cargo vessel is a carefully orchestrated process, akin to a well-rehearsed choreography. It begins with the creation of 3D models and simulations, which serve as a visual aid, allowing for the meticulous planning of every movement and placement of the MDF panels. This digital rehearsal ensures that, when it comes to the actual loading, each panel is stowed in the most effective manner, taking into account balance, weight distribution, and space optimization.

When it comes to space utilization, it’s an exact science that requires innovative methods to maximize the efficiency of the cargo hold. Drawing on the expertise of seasoned Thai stevedores, here are some professional tips for maximizing space:

- Stack MDF panels flush against each other to eliminate wasted space.

- Use vertical and horizontal strapping to secure stacks and prevent movement.

- Employ honeycomb stacking techniques where feasible to enhance stability.

Protecting MDF during transit is paramount. To shield MDF from potential damage, several techniques are employed. New materials such as impact-resistant corner covers and breathable water-resistant wraps are used to safeguard the panels. Additionally, protective gear for the cargo includes:

- Vibration dampening mats to absorb shocks and reduce movement.

- Edge protectors to guard against chipping and pressure marks.

- Non-abrasive covers to prevent surface scratches during handling.

By following these loading strategies, MDF can be transported across the seas with minimal risk of damage, ensuring that this valuable commodity arrives in pristine condition, ready for its wide array of applications in the global market.

The Art of Securing MDF Cargoes

The process of securing MDF cargoes for sea transit is a nuanced blend of practical application and theoretical knowledge. It is a procedure where the chosen securing materials are as vital as the methods used to apply them. The selection of armor for MDF cargoes involves an understanding of various materials, their properties, and how they function under the specific conditions of maritime transport.

- Lashing Materials: Lashing is central to securing MDF, with materials ranging from wire ropes to steel strapping. The choice of lashing material depends on factors like the size of the cargo and the expected weather conditions. The most commonly used are:

- Wire ropes, typically 12–18mm in diameter, for their strength and flexibility.

- Steel strapping, for its ability to maintain tension over long durations.

- Dunnage: Dunnage serves as the cushion between the MDF cargo and the vessel’s structure, preventing movement and chafing. It also facilitates air circulation, which is crucial for MDF, as it is sensitive to moisture. Types of dunnage include:

- Wooden planks or boards, often referred to as ‘sheep wood.’

- Foam padding for delicate or finely finished surfaces.

- Blocking and Bracing: These techniques involve using wood or metal bars to create a frame that holds the MDF in place. This framework must be designed considering the dynamic forces the ship will encounter at sea.

- Tie-down Points: The placement of tie-down points is a critical consideration. These are used in conjunction with turnbuckles or other tightening devices, which allow for adjustments to be made as necessary throughout the voyage.

The dynamics of stability come into play with the application of these materials. Marine engineers contribute their expertise to ensure that cargoes are balanced and secure, applying principles of physics to calculate the best arrangement for stability. This includes assessing the vessel’s roll period, the distribution of weight, and the center of gravity of the cargo.

Stress tests and simulations form an integral part of the pre-voyage preparations. Using virtual modeling, the securing setup is evaluated under a range of simulated conditions to identify potential issues. This might involve:

- 3D Simulations: Detailed visualizations of the cargo layout and securing methods.

- Dynamic Stress Testing: Simulating the forces the cargo will face during transit, such as the ship’s movements and weather conditions.

- Iterative Revisions: Adjusting the securing methods based on feedback from simulations to optimize the process.

This meticulous approach to securing MDF, informed by the practices outlined by Bond Thailand Marine Services, ensures that the cargo can withstand the rigors of sea transport without shifting or sustaining damage. The resulting stability and security of the cargo not only safeguard the material itself but also contribute to the safety of the entire vessel. By combining the best of materials, engineering principles, and virtual technology, the art of securing MDF cargoes becomes a science, ensuring that these vital goods reach their destination intact.

Climate Challenges and MDF

Medium Density Fiberboard (MDF) faces significant challenges when it comes to the tropical climate of Thailand, with its high humidity and heat. The effects of such a climate on MDF can be profound, leading to issues such as warping, swelling, and a loss of structural integrity.

Dealing with the tropical climate’s impact on Medium Density Fiberboard (MDF) during transit and storage involves a strategic approach to counteract the effects of high humidity and heat. From the detailed insights provided by Bond Thailand Marine Services and the extensive experience in handling MDF, several best practices have been identified.

Battling Humidity and Heat:

- Advanced Protective Wrapping: Utilizing specialized wrapping materials that offer robust protection against moisture. This includes vapor barrier films and moisture-resistant coatings that are particularly effective in Thailand’s humid climate.

- Enhanced Packaging Solutions: Employing corner protectors and edge sealants to safeguard the MDF from moisture ingress and physical damage. Also, the use of desiccants within the packaging to absorb excess moisture.

- Climate-Sensitive Storage Facilities: Utilizing warehouses with climate control systems, including dehumidifiers, to maintain a stable environment for stored MDF.

Innovative Protective Measures:

- Water-Resistant Tarpaulins: Using large tarpaulins that are water-resistant to cover MDF during outdoor storage or while in transit, especially critical during the rainy season.

- Regular Inspection and Maintenance: Conducting routine checks on the MDF’s condition and the effectiveness of protective measures, adjusting strategies as required.

The Container Microclimate:

- Container Ventilation: Implementing ventilation systems in containers to minimize moisture buildup and condensation, which are detrimental to MDF.

- Monitoring and Control Devices: Equipping containers with advanced sensors to continually monitor and regulate the internal atmosphere, ensuring a balance in temperature and humidity.

- Adapting Container Environment: Using climate-controlled containers for highly sensitive MDF cargoes to preserve the material’s quality during long transits.

These practices, combined with the rich experience of Bond Thailand Marine Services in handling MDF cargoes, provide a comprehensive approach to mitigating the effects of Thailand’s climate on MDF. By incorporating these strategies, MDF can be transported and stored effectively, ensuring that it retains its quality and structural integrity upon arrival at its destination.

Navigating the Paper Seas

Documenting the Voyage:

Managing the documentation for MDF cargoes involves a thorough understanding and preparation of a wide range of documents. These documents serve various purposes from legal compliance to logistical tracking. Here’s an exhaustive list of necessary documentation, often elucidated through interactive checklists and flowcharts for ease of understanding and implementation:

- Bill of Lading (B/L): Serves as the key document of title, providing evidence of the contract of carriage, receipt of goods, and the terms and conditions under which the goods are carried.

- Cargo Manifest: Details all the cargo carried on the vessel, including a description, quantity, and destination.

- Packing List: Specifies how the MDF is packed and identifies the marks and numbers on the packages.

- Certificate of Origin: A document that certifies the country in which the MDF was produced.

- Phytosanitary Certificate: Required for wood products to certify that the MDF is free from pests.

- Insurance Certificates: Providing proof of insurance coverage for the cargo.

- Safety Data Sheets (SDS): Especially crucial for any chemicals or hazardous materials used in the treatment or production of MDF.

- Stowage Plan: Illustrating how and where the MDF is stowed on board the vessel.

Legal Labyrinths:

Navigating the legal aspects of MDF transport involves understanding and complying with both Thai and international maritime regulations. These laws govern everything from the handling and stowage of the cargo to environmental and safety standards. Commentary from legal experts sheds light on complex regulations, helping to decipher and navigate these legal labyrinths. Key areas of focus include:

- International Maritime Dangerous Goods (IMDG) Code: For MDF treated with certain chemicals, compliance with IMDG regulations is essential.

- International Maritime Solid Bulk Cargoes (IMSBC) Code: Although MDF is not a bulk cargo, some aspects of the IMSBC Code may be relevant, especially regarding stowage and securing.

- Maritime Labour Convention (MLC): Ensuring crew welfare and safety standards are met during the transportation of MDF.

- Port State Control Regulations: Compliance with regulations of the destination port state, which may have specific requirements for MDF cargoes.

Understanding and meticulously managing these documents and legal requirements are essential for the smooth transportation of MDF cargoes. It ensures compliance with international shipping standards and the efficient, safe delivery of the cargo.

Unloading – The Final Frontier

Unloading Medium Density Fiberboard (MDF) is a critical phase where precision and care are paramount. The process involves not only the physical removal of cargo from the vessel but also ensuring its integrity is maintained post-unloading.

The unloading procedure is a carefully orchestrated process that involves several key steps:

- Safety Briefing: Prior to unloading, a safety briefing for all personnel involved is crucial to prevent accidents and ensure smooth operations.

- Equipment Preparation: Ensuring that all necessary unloading equipment, such as forklifts and cranes, are in place and functioning correctly.

- Unloading Plan: Following a well-structured unloading plan that details the sequence in which the MDF cargoes are to be removed.

- Systematic Unloading: Methodically unloading MDF cargoes using appropriate lifting techniques to prevent damage.

- Monitoring and Supervision: Continuous monitoring and supervision by experienced personnel to quickly address any issues that arise during the process.

Once offloaded, the proper storage and handling of MDF are crucial to maintain its quality:

- Controlled Storage Conditions: Storing MDF in environments where humidity and temperature are controlled to prevent warping or swelling.

- Handling and Transportation: Using proper handling techniques and equipment during transportation to the storage area to avoid damage.

- Stacking and Storage: Storing MDF in a manner that prevents bending or pressure marks, often involving stacking with spacers to allow air circulation.

- Inspection and Maintenance: Regular inspection of stored MDF for signs of damage or deterioration and maintaining ideal storage conditions.

By adhering to these procedures and best practices, the unloading of MDF can be conducted safely and efficiently, ensuring the product’s integrity from the point of disembarkation to its final destination. This final phase in the cargo’s journey is as crucial as any other, requiring meticulous attention to detail and expert handling.

Real-World Cargoes Operation

For a comprehensive understanding and a deeper dive into these real-world experiences, We are encouraged you to visit the Work Portfolio Page of Bond Thailand Marine Services. Here, you will find a rich repository of case studies, interviews, and analyses that not only demonstrate our company’s expertise in MDF cargo handling but also offer valuable insights into the complexities and intricacies of maritime cargo operations. The resource serves as a testament to the company’s commitment to excellence and its role as a leader in maritime cargo handling services.

Conclusion

In summary, adept handling of MDF cargoes mirrors the essential skills needed in maritime logistics, combining human expertise, technological progress, and strategic planning. Thailand’s proficiency in this area reflects its commitment to excellence and its significant role in the global economy.

Appendices

Glossary of Maritime and MDF Terms:

- Bill of Lading (B/L): A document issued by a carrier to acknowledge receipt of cargo for shipment.

- Dunnage: Material used to protect cargo during transportation.

- Desiccants: Substances that absorb moisture, used to keep environments dry.

- IMDG Code: International Maritime Dangerous Goods Code, a standard for the safe transportation of dangerous goods and marine pollutants in international shipping.

- IMSBC Code: International Maritime Solid Bulk Cargoes Code, providing safety guidelines for the shipment of solid bulk cargoes.

- Phytosanitary Certificate: A document stating that a shipment has been inspected and is free from harmful pests and diseases.

- Stowage Plan: A plan showing the distribution of all cargoes on board a vessel.

- Turnbuckle: A device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems.

Resources:

- “Cargo Handling and Stowage” by Peter Grunau.

- “Technical Bulletin – Storage and Handling of Particleboard and MDF.” https://www.compositepanel.org/wp-content/uploads/TB-Storage-and-Handling.pdf

- Annex 2E, Summary of Lessons Learned from Casualties for Presentation to Seafarers.

- PanelGuide 2014 Annex 2E.

Contact Our Expert:

For specialized advice and insights, contact our team at Bond Thailand Marine Services. Reach out for consultancy on maritime operations, cargo handling, and industry best practices.

- Contact Information:

- Phone: +6684-800-3868

- Email: operation@bondth.com

- Office Address: 120/ 15 Moo 8, Tinsulanonda Road, Khao-Rup-Chang Sub-district, Muang District, Songkhla Province, 90000

Our team, consisting of seasoned maritime professionals and experts in MDF handling, is ready to provide comprehensive support and guidance for your shipping needs.