‘Around 90% of world’s goods are transported by sea.’

These words is commonly used to described the importance of logistics business. It seems a little exaggerated, but that’s what really happened. Transporting goods via ships can be loaded with tonnes of goods which makes it the most cost-effective way.

Delivering to a customer goods without any damages is one of major concerns for the logistics business. Any unexpected conditions could happen during the course of transportation. Some are really severe. So, prevention should be established to secure the goods.

Wood has been applied as a material for many kinds of works for a long time. And, for sea transportation, apart from being used for building a ship as we obviously know, wood has been used to stabilize and organize goods. We will discussed about it here.

Types of Wood Application to Goods in Transportation

In logistics, we usually find these 2 types of application for wood.

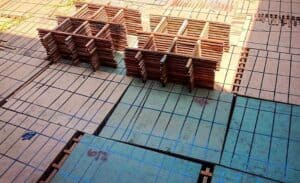

1. Pallet

Pallets have been generally used for organizing goods in order to load, stack, store, move, and ship. It is designed to support high weight and is easy to be moved as it has holes at its base for a fork lift. Most importantly, it is cheap.

Categorizing pallets can be done in 3 ways which are by entry points, by design, and by material. An entry point of a pallet is a hole for a fork lift. There are 2 types which are two-way and four-way entry points. The design of a pallet takes weight support into account. This makes a Stringer Pallet can bear an extra weight over a Block Pallet. And, as various material can be used to create a pallet, so the material is used to described a pallet.

The size of a pallet, if not observe carefully, appears to be the same. But, there is a slightly different in its dimensions. There are Euro (80 x 120 x 15 cm), Japan (110 x 110 x 15 cm), and Thai (100 x 120 x15 cm). The name implies the region it is often used.

Pallet use in logistics industry

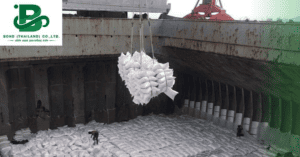

2. Dunnage

Originally, dunnage means the belongings of travelers aboard ships, trains, and caravans. But today, dunnage refers to the various materials used for stabilizing products to prevent in-transit damages.

As well as a pallet, any materials can be used to create dunnage. But wood is the most popular due to its availability anywhere around the world.

It is impossible to arrange goods to perfectly fit within a container or a storage area. There will always be some gaps left. These gaps, even very little, could become a cause for products’ damages or broken. If the products are also fragile, the situation will be worse, causing unwanted additional cost and, in the worst case, lawsuit. To avoid it, the products need to be kept still so it will not crash to each other or to other things.

The wood for dunnage can be new or recycled. However, it must be strong and durable enough to hold and brace the products.

Lumber use for Cargo dunnage

An International Standard for Wood Shipped Internationally

Products for export should pass some international standards. This also apply to wood for dunnage.

International Standards for Phytosanitary Measures No. 15 : Guidelines for Regulating Wood Packing Material in International Trade (ISPM 15) developed by International Plant Protection Convention (IPPC) is the standard which regulated the export of wood.

ISMP-15 provides guidance for establishing measures to minimize the risk of pest movement including: the removal of bark; the application of a treatment, and; the identification of compliant wood packaging material with an internationally recognized mark. Types of wood packaging material hereby includes dunnage, crating, packing blocks, drums, cases, load boards, pallet collars, skids or pallets and other wooden units which secure, protect or assist in the movement of a cargo or commodity.

ISPM 15 excludes articles made from wood thinner than 6 mm and wood packaging material made exclusively from processed wood material such as plywood, oriented strand board, fibreboard, press board, cardboard, etc. The latter articles have either undergone processes that render them a negligible risk, or the nature of the material used poses little pest risk. The thin layers of wood laminated together to construct sheets of plywood are unlikely to contain most forest pests. Oriented strand board, fibreboard, etc. are made from small chips of wood glued together under heat which are unlikely to contain pests.

A Trusted Supplier will Provide Quality Wood

Bond Thailand supply quality wood for creating dunnage and pallets. Our lumber supply sources wood locally and responsibly. Our hardwood is unmatched in volume and variety. We pride ourselves on the services. No matter the sizes or volumes you demand, we can accommodate your application. Our team are dedicated to guarantee you 100% confidence that our wood is price-competitive and strong to endure the toughest conditions.